Approach to Reduce Environmental Impact

Installation of Boiler Using 100% Waste Cooking Oil

In April 2021, we began using a waste cooking oil boiler at our Tohoku Plant that uses 100% of the waste cooking oil generated at production plants as fuel.

We reduced CO2 emissions by approximately 1,200 tons per year by using vegetable-derived waste cooking oil instead of the traditional heavy oil.

Waste cooking oil boiler installed at the Tohoku Plant

100% reuse of chicken manure (installation of boilers/composting)

Chicken manure collected from the poultry house (YONEKYU OISHII TORI CORP., Tottori and Shizuoka) is 100% recycled. We have installed a boiler that can use chicken manure as fuel, and use the heat source for floor heating in the poultry house to help create a comfortable growing environment for the chickens, and reuse it for hot water used in the factory. We are also working to reduce our environmental impact by composting chicken manure.

We collect chicken manure regularly and reuse 100%

Boiler fuel conversion and Installation of solar panels

We are promoting initiatives to reduce emissions by switching the fuel used in boilers at our production sites from heavy oil to city gas or LPG, as well as installing rooftop solar power generation equipment.

In fiscal year 2024, we installed solar power generation equipment at four sites. Going forward, we will continue to consider expanding these initiatives to other production sites and promoting the procurement of renewable energy in order to reduce GHG emissions.

Fuel conversion of boilers at Hokuriku Plant

Solar panels at the Rokko Plant

Solar panels at the Nishinomiya Plant

Installation of a Cogeneration System

We installed a cogeneration system in February 2022 at the ASAKUSA HAM Kanto Plant.

A cogeneration system is an energy-efficient power generation system that generates electricity using city gas as fuel and captures and utilizes the heat emitted.

We anticipate a reduction in CO2 emissions due to the reduced operating time of our existing steam boilers, and are considering introducing this system at other plants as well.

A cogeneration system at the ASAKUSA HAM Kanto Plant

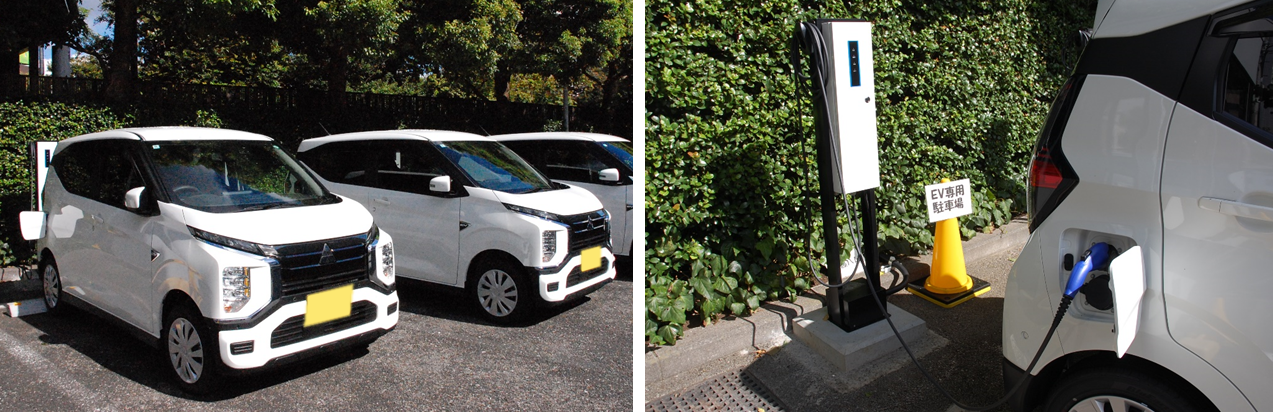

Introduction of EV vehicles (electric vehicles)

EVs (electric vehicles) were introduced as part of the Meguro Office company fleet for environmental considerations.

EV company vehicles and charging facilities at the Meguro office

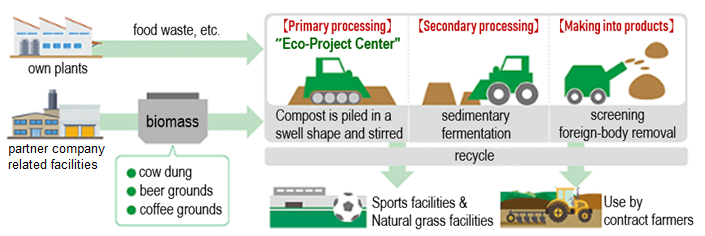

Food Waste Recycling

We operate a food waste recycling activity takes place at the Yonekyu Eco Project Center (Asagiri, Fujinomiya City, Shizuoka Prefecture).

The center recycles food waste from our plants and from subcontractors to produce approximately 500 tons of high-quality fertilizer (Compost Power ) annually.

The fertilizers are used by contract farmers and for various other purposes, reducing our environmental impact.

YONEKYU Eco Project Center and compost expansion work